Dive Brief:

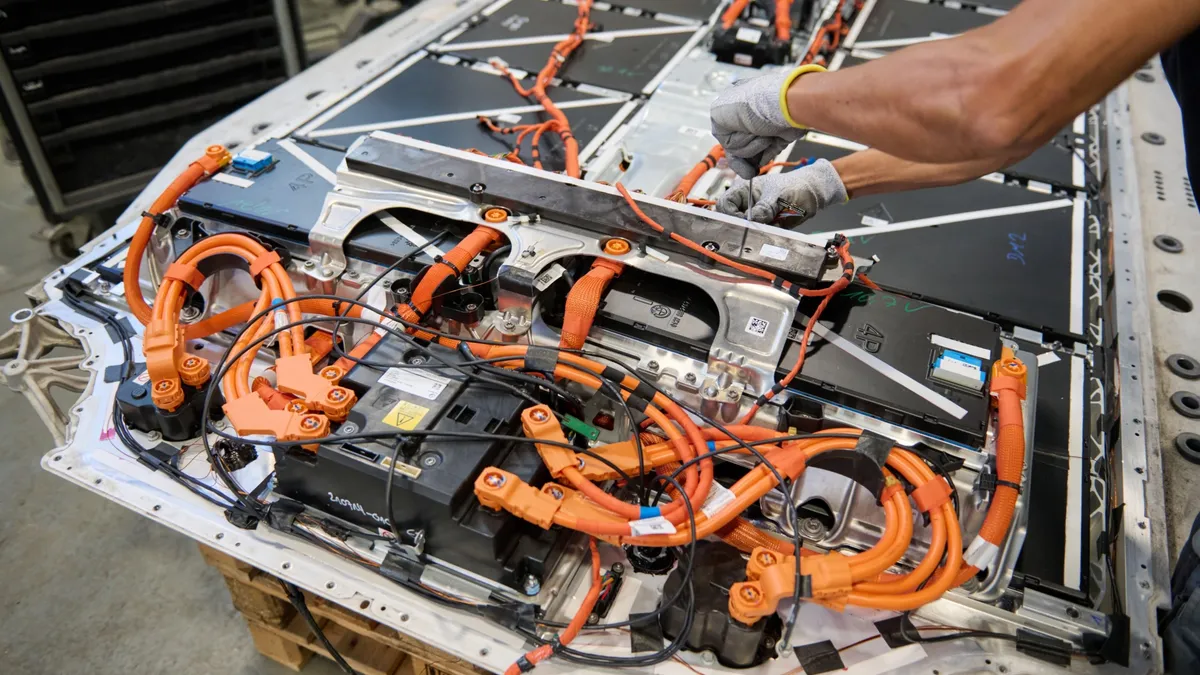

- BMW Group and Singapore-based SK tes launched a European battery recycling partnership to recover cobalt, nickel, and lithium from used batteries, the automaker announced Monday.

- Recovered materials will be returned to BMW’s supply chain to produce new batteries, creating a circular recycling ecosystem for end-of-life batteries. The first batteries produced with recycled raw materials will be used in BMW’s next-generation “Neue Klasse” electric vehicles.

- The closed-loop battery recycling partnership with BMW will later expand around the globe, and is set to expand to the US-Mexico-Canada region as early as 2026, according to the release.

Dive Insight:

As part of the partnership, high-voltage batteries from the automaker's Europe-based facilities will be shipped to SK tes for recycling. BMW will also be directly involved in the battery recycling processes and will provide feedback and insights.

Sk tes mechanically shreds used batteries and concentrates them into black mass, a material created from battery scraps that is further processed to recover critical raw materials like nickel, lithium and cobalt. The company claims it can recover and recycle up to 99% of the materials from used batteries.

"The promotion of circular economy is an important strategic topic for the BMW Group,” said Nadine Philipp, VP sustainability supplier network at BMW in the release. “The development of recyclable products, the increase of secondary materials in our components, and the closing of loops play an equally important role.”

The battery recycling partnership with SK tes follows a separate agreement between BMW and U.S.-based Redwood Materials announced in September to recycle end-of-life batteries from both hybrid and electric BMW vehicles. Redwood Materials aims to return 95% to 98% of these critical minerals back to the battery supply chain.

"Partnerships like this increase our efficiency in terms of the circular economy,” Jörg Lederbauer, VP of circular economy, spare parts supply high-voltage battery and electric powertrain at BMW, said in a statement.

Outside of batteries, BMW has been recycling entire vehicles for over 30 years at its Recycling and Dismantling Center in Munich. Vehicles used for testing that cannot be sold are dismantled using a standardized process that focuses on identifying reusable components and materials suitable for recycling.