Dive Brief:

- General Motors has acquired Tooling & Equipment International, a company that designs, engineers and manufactures gigacasting machinery for automakers, the company confirmed in an email. Reuters was the first to report the news on Wednesday.

- Prior to GM’s acquisition, the Michigan-based company was working with Tesla to improve its vehicle manufacturing techniques, including designing massive presses that can cast more complex structural components for its electric vehicles, Reuters reported.

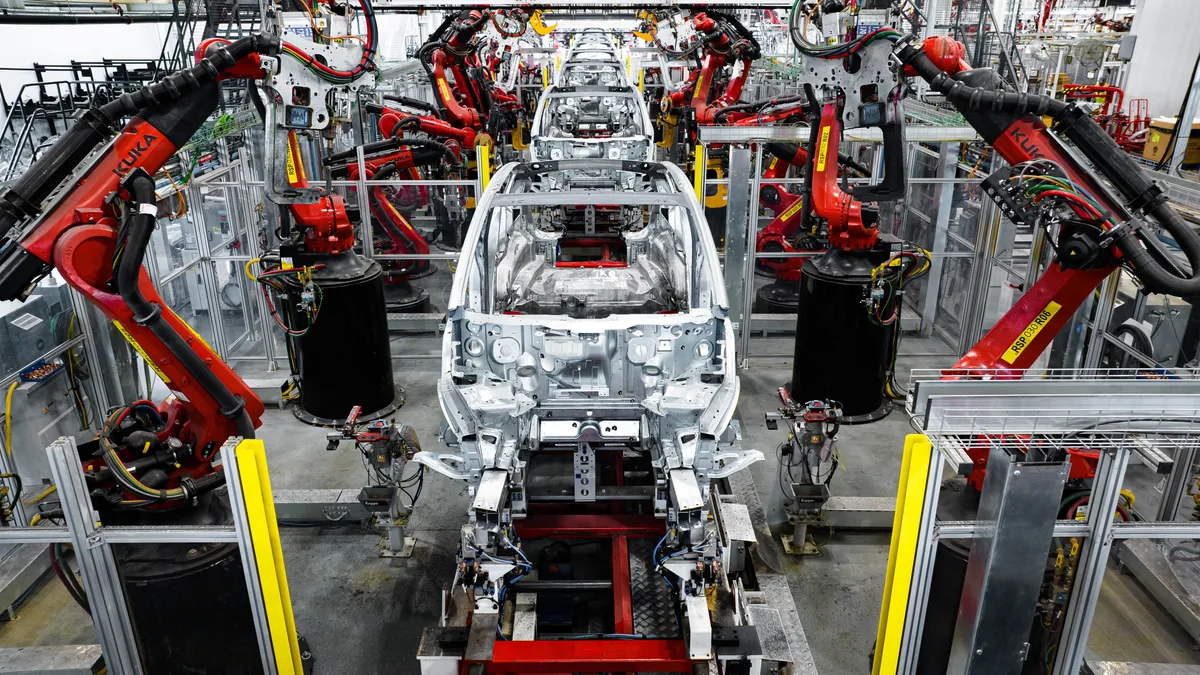

- Gigacasting presses can reduce the steps and robotic equipment needed to produce aluminum vehicle bodies, which could allow GM to reduce manufacturing costs and sell more affordable EVs.

Dive Insight:

At Tesla’s Investor Day event in March, the company touted gigacasting as a manufacturing breakthrough that would help it mass produce cheaper EVs by the millions in the future. Other automakers, including Hyundai and Toyota, are also exploring how gigacasting can streamline vehicle manufacturing.

“Bringing TEI into the GM enterprise builds on decades of the company’s own casting experience and provides a competitive advantage with strategic castings for future low-volume products like the Cadillac CELESTIQ,” a GM spokesperson said in an email.

Gigacasting uses high-pressure molds to form and stamp aluminum body structures as a single unit, eliminating hundreds, or even thousands of welds that are typically needed to assemble body separate components in conventional vehicle production.

According to Reuters, TEI helped make Tesla’s gigacasting breakthroughs possible. Four sources told the outlet that Tesla has been working with TEI since 2017 when it was developing the Model Y. Two told Reuters that TEI also worked with Tesla more recently on gigacasting prototyping for the Model 3, Cybertruck and electric semi truck.

“GM acquired TEI to bolster its portfolio of innovations and secure access to unique casting technology,” the automaker said in an email.

In September, Toyota demonstrated a prototype of its new gigacasting equipment at an assembly plant in Japan. The gigacasting machine can produce one-third of a vehicle’s body in about three minutes. These sections are normally built from 86 individual parts in a 33-step process that takes Toyota hours to complete. Toyota plans to implement gigacasting production methods for a vehicle in 2026.

As part of the deal, TEI will continue to operate independently, with GM serving as its parent company.

GM did not disclose the financial terms of the deal.