Dive Brief:

- Toyota will work with Cirba Solutions, a North Carolina-based battery recycling materials and management company, to expand battery recycling in the U.S., according to a press release Thursday.

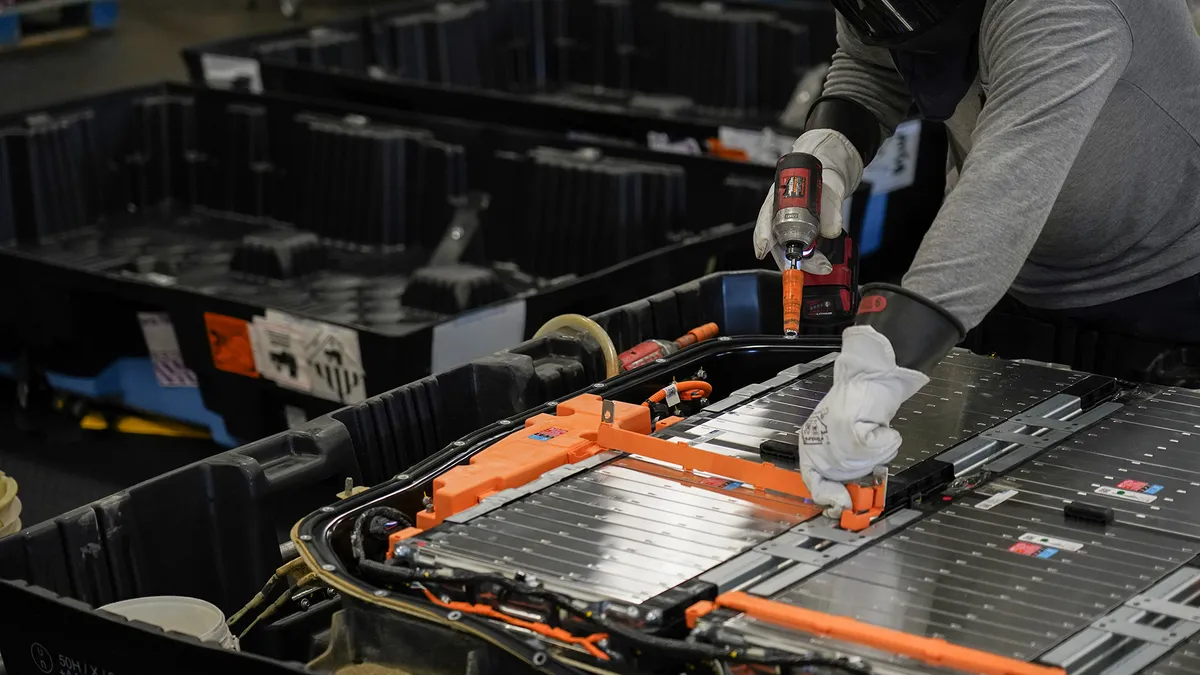

- As part of the partnership, Cirba Solutions and Toyota will focus on the collection, transportation, dismantling and processing of Toyota’s end-of-life lithium-ion batteries from the Midwest and East Coast regions of the U.S.

- The plans are part of Toyota’s goal of ramping up EV production, establishing a closed-loop battery ecosystem and becoming carbon neutral across all its global manufacturing facilities by 2035.

Dive Insight:

The partnership with Cirba Solutions will help expand Toyota’s U.S. battery recycling network and its logistics to transport end-of-life batteries from the automaker’s hybrid and future electric vehicles, the company said.

The batteries will be processed at Cirba Solutions’ facility in Lancaster, Ohio. Cirba Solutions said its technology can recover up to 95% of the critical raw materials from used batteries, which will be used to manufacture new ones and help bolster the domestic supply chain.

“Our collaboration with Toyota helps move toward a long-term vision of a sustainable closed-loop battery supply chain,” said Jay Wago, chief commercial officer at Cirba Solutions.

Toyota said it currently collects approximately 25,000 used automotive batteries a year from its dealerships, a majority of which are nickel-metal hydride batteries used in hybrid vehicles. However, as the automaker produces more EVs, it predicts the number of end-of-life batteries recycled from its vehicles could double by 2030.

The partnership will also help Toyota reduce its transportation and logistics costs by at least 70%, according to the company. Toyota expects the average miles driven to collect end-of-life batteries will be reduced by over 650 miles, which can significantly reduce logistics-related emissions.

“Cirba Solutions’ large and well-established transportation and recycling network ensures Toyota has nationwide battery collection and recycling to reduce both our costs as well as our operational carbon footprint,” said Christopher Yang, group vice president of business development at Toyota Motor North America.

Despite Toyota’s push to reduce its carbon footprint, the car manufacturer’s scope 1 and scope 2 emissions increased in 2023 from the year prior, according to its latest sustainability report released earlier this month.

Cirba Solutions recently received over $82 million in grants from the U.S. Department of Energy. It was the first company to receive funding under the DOE's Office of Manufacturing and Energy Supply Chains grant program as part of the Bipartisan Infrastructure Law, which aims to expand domestic manufacturing of batteries for EVs.

The new partnership with Cirba Solutions builds on Toyota’s other recycling initiatives in the U.S.

Last month, Toyota said it will source recycled cathode active materials and anode copper foil from Redwood Materials. The automaker intends to use the recycled materials to produce new batteries at its upcoming North Carolina battery manufacturing plant.

Redwood aims to supply Toyota with at least 20% recycled nickel and lithium, 50% recycled cobalt and 100% recycled copper for battery cell production.

Toyota plans to triple its EV production target in 2025 to 600,000 vehicles.

In the interim, Toyota has set a production target of 190,000 battery-powered vehicles for 2024.