Dive Brief:

- Toyota is developing and adopting several new technologies to support its transformation into an electric mobility company, according to a company news release Tuesday.

- The automaker plans to streamline its electric vehicle manufacturing processes with new, modular designs, giga-casting and self-propelling production technology to lower the costs of production and factory investments.

- Toyota’s renewed EV strategy will help support its plans to invest more than $70 billion in electrification by 2030.

Dive Insight:

In March, Toyota announced it shifted more than half of its R&D staff and budgets to accelerate its work on electrification, advanced battery technologies, software-based vehicles and streamlined manufacturing efficiencies to reduce costs.

Toyota’s future BEVs will feature advanced batteries delivering driving ranges of 1,000 km (621 miles) or more, according to the company. The automaker plans to reduce battery costs by 20% compared with the current Toyota bZ4X EV battery pack, its first electric SUV.

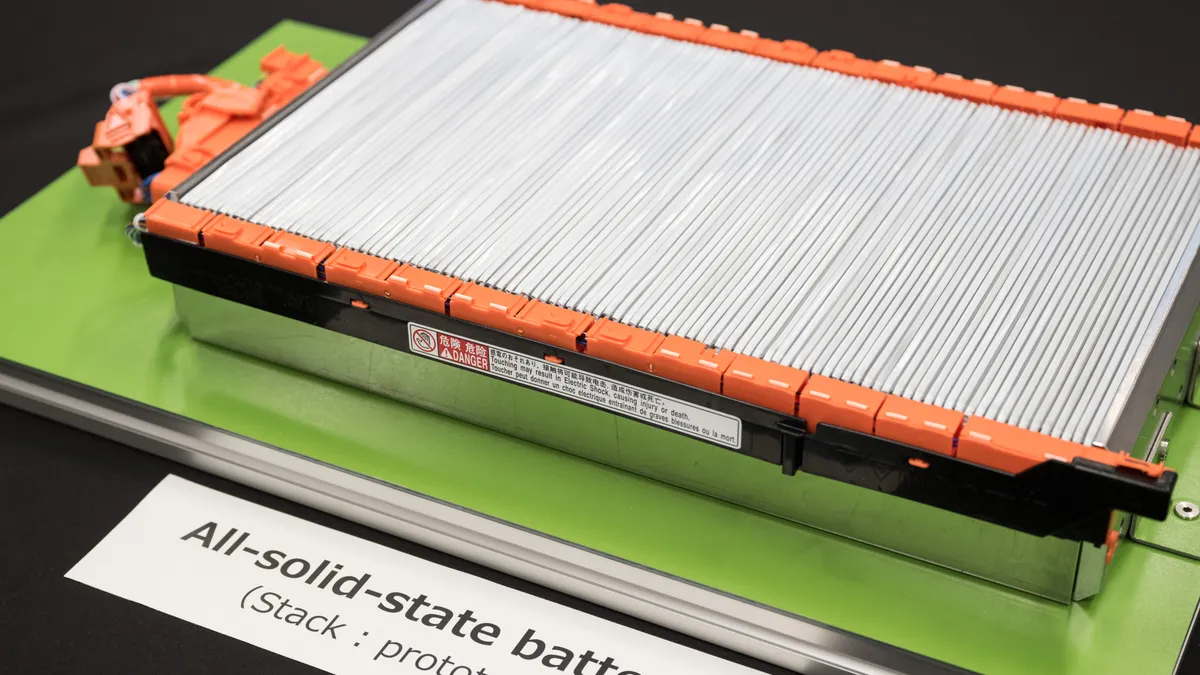

As part of these new corporate initiatives, Toyota plans to improve the energy density of its current lithium-ion batteries and eventually introduce high-performance solid-state batteries that use no liquid electrolyte. Targeted charging times for Toyota's future EV are 10-20 minutes.

The automaker is developing two distinct battery chemistries, a low-cost design for its mass-market EVs and a higher-performance version, according to a technical document from the automaker. The low-cost batteries are intended to promote EV adoption, allowing Toyota to offer more affordable EVs. These batteries will be lithium iron phosphate and debut in 2026-2027 Toyota models. Compared to today’s batteries, Toyota is aiming for a 20% improvement in range and a cost reduction of 40%, with fast charging times of 30 minutes or less.

Toyota’s next-generation, high-performance lithium-ion batteries will incorporate a more advanced, bipolar structure with a high nickel cathode to achieve even greater performance. Compared to current EV battery technology, Toyota is targeting a 10% improvement in both range and costs, with charging times of 20 minutes or less.

Toyota also plans to introduce new solid-state batteries for 2027-2028 models. These batteries are currently in development and could offer 50% more driving range compared with EVs on the road today.

Future Toyota vehicles will also include a modular chassis consisting of a front, rear and center portion that can be used for multiple models. This highly modular design reduces complexity and can significantly reduce manufacturing costs. Vehicle bodies will be assembled using giga-casting, a process pioneered by Tesla to reduce the number of welded components and create a single rigid body structure.

Toyota’s next-generation BEVs will also feature aerodynamic designs to reduce drag to improve range. These aerodynamic improvements are based on hypersonic rockets and are being studied in cooperation with the Space Systems Division of Mitsubishi Heavy Industries.