Japan-based chipmaker Renesas Electronics signed a $2 billion agreement with Wolfspeed for a 10-year supply of silicon carbide wafers on Wednesday.

Under the agreement, silicon carbide technology leader Wolfspeed will provide 150mm silicon carbide bare and epitaxial wafers needed for Renesas to scale production of its silicon carbide power semiconductors starting in 2025.

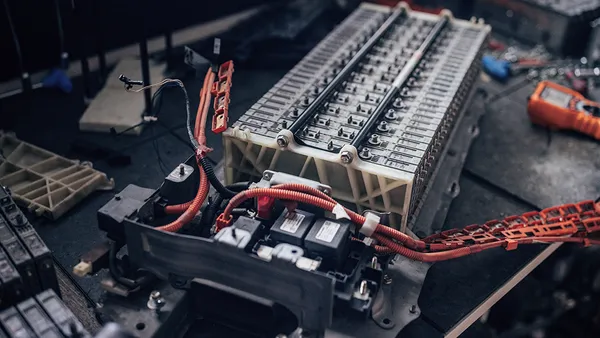

A wafer, traditionally made from silicon, is a thin piece of semiconductor material used to make microchips. The companies said demand for chips made from silicon carbide is rising over silicon chips as the material offers greater energy efficiency and power density at a lower price point.

The shift to EVs and renewable energy has sparked a growing need for more efficient power semiconductors, which supply and regulate electricity, according to the North Carolina-based company.

“With the steepening demand for silicon carbide across the automotive, industrial and energy sectors, it’s critically important we have best-in-class power semiconductor customers like Renesas to help lead the global transition from silicon to silicon carbide,” President and CEO of Wolfspeed Gregg Lowe said in a statement.

The company also anticipates supplying Renesas with 200mm wafers once its new production facility for silicon carbide materials is fully operational.

“The wafer supply agreement with Wolfspeed will provide Renesas with a stable, long-term supply base of high-quality silicon carbide wafers. This empowers Renesas to scale our power semiconductor offerings to better serve customers’ vast array of applications,” President and CEO of Renesas Hidetoshi Shibata said in a statement.

Renesas is working to meet demand for more efficient power semiconductors at its factories in Japan. The company announced plans to restart production of insulated-gate bipolar transistors, a semiconductor device used to switch power on and off with high energy efficiency, at its Kofu factory, and is establishing a silicon carbide production line at its Takasaki factory.