In the fast-paced world of automotive engineering, a new race is underway – not on the track, but in factories and meeting rooms across the globe. The end goal? A truly sustainable supply chain that can meet the growing demands of an environmentally conscious consumer market without compromising on quality or innovation. As we navigate this intersection in the automotive industry, it's clear that sustainability is no longer just a buzzword but a fundamental force for industry change.

The automotive supply chain is complex, stretching across countries, continents and involving hundreds if not thousands of suppliers. Traditionally, this supply chain has been enhanced for cost and efficiency. However, things are changing, driven by a combination of consumer demands, regulatory and industry pressures, and a growing recognition of the urgent need to address climate change.

One of the main challenges facing the industry is to reduce the carbon footprint. This includes addressing areas such as raw material extraction and assembling new vehicles. There is also a need to steer away from using the rare earth elements and other natural materials needed in some production lines, replacing them with more sustainable alternatives.

Additionally, waste management is a challenge; this needs to be an area of focus, as the automotive industry generates significant waste, both during production and at the end when the vehicle is no longer being used.

One more challenge that faces many industries, but is common in the automotive industry, is traceability. Ensuring ethical and fair practices throughout the supply chain is an area that continues to be difficult and requires attention so that it is as transparent as possible.

So, what can we do to help? Despite these challenges, the industry is making remarkable strides towards sustainability. For example, industry leaders are embracing circular economy principles and designing vehicles with end-of-use recycling initiatives. This involves developing easily-dismantable components, increasing the use of recycled materials in new vehicles and implementing take-back programs for end-of-use vehicles. These innovative solutions could help to significantly reduce the environmental impact of automakers whilst helping to lower production costs in the long run.

There has been and continues to be a revolution in materials science. This has been led by the industry looking for new fuel efficiencies and reduced emissions. Initiatives that have come out of this steady revolution include changes in materials such as using more high strength, low-weight alloys, carbon fibre reinforced plastics and bio-based materials. These initiatives not only reduce the weight of vehicles, improving fuel efficiency, but also often have a lower environmental impact when being produced.

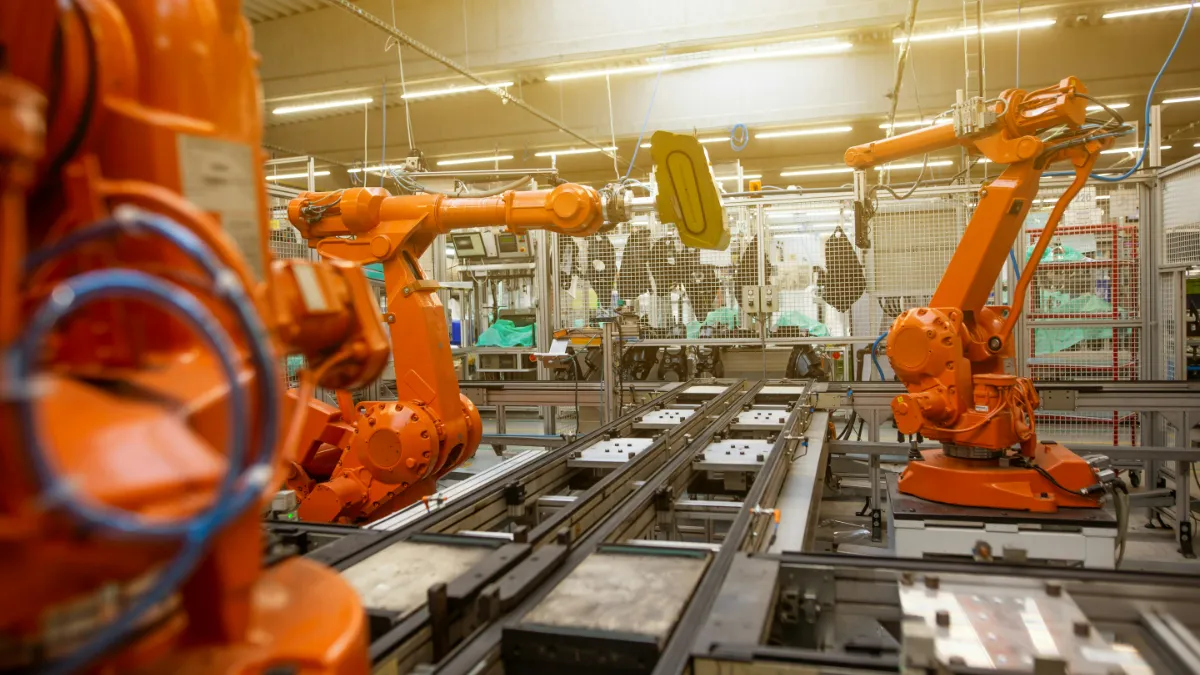

AI and new technologies, such as IoT technologies, are being used across industries and the world, and the automotive industry is no exception to this. The use of technology, specifically digital supply networks, is helping to reduce waste, time and improve overall efficiency. This, along with trying to source materials and equipment closer to the assembly plants and factories, shortening supply chains, helps to reduce waste and transport-related emissions. This would also help support local economies, strengthening local job markets for many workers.

Some automakers are increasingly looking to and using renewable energy to power their factories and operations. This includes the use of solar energy and wind power and even encouraging their suppliers to use cleaner, renewable energy sources, too. In attempting to clean their energy supply, they can drastically reduce their carbon footprint and those of their products.

Going one step further from encouraging their suppliers, some automakers could form partnerships with suppliers who are specifically committed to positive environmental impacts and changes. Strategies employed in these partnerships may include sharing KPIs and goals, metrics and targets around green initiatives and best practices. These would help foster innovation, creativity and encourage others to follow these examples to help the industry pivot to more sustainable processes.

While innovative and positive progress is being made, key challenges remain. Some of these may be connected to factors such as those in the wider economic landscape, across global governments and from political and societal changes. The initiatives discussed in this article may require significant financial investment, a change in culture within the automotive industry and automakers, changes to regulations and government financial support and incentives, and consumer culture and trends (and potentially, financial incentives).

So, is it possible to revolutionize sustainability in the automotive industry? Perhaps the answer is that it isn’t an easy answer. It won’t be without its challenges. However, this industry is making many strides and showing impressive resilience in its innovations to address these challenges. It has the potential to be a leading industry for change.

It seems that sustainability in the automotive supply chain is not just an environmental imperative but a business one. Automakers that lead in this area will likely be better positioned to meet evolving market changes, regulatory requirements and satisfy consumer demands and questions. They could ultimately thrive in an increasingly competitive global market.

To summarize, the race to sustainability in automotive engineering is long and complex, but with continued innovation and creativity, the industry is well-positioned to turn this challenge into an opportunity for positive change and efficiency. The race is on, and you could argue that the winners will be those who can most effectively balance performance, profitability and the planet in their pursuit of a truly sustainable automotive industry.