IAV is one of the world's largest engineering companies. Within an extensive portfolio geared toward the future of mobility, battery development plays a critical role. A team of IAV engineers, including technical consultant Jakob Hilgert felt that, with the right approach, IAV could achieve better battery designs. The team leaned on its understanding of what makes existing single-chemistry designs successful — as well as what holds each back — to develop a novel approach to solving battery energy density, sustainability, and thermal management issues: a twin-battery design.

Instead of turning solely to lithium-ion cells, IAV engineers thought a pair of alternative battery chemistries could be combined to form a less expensive and more ecofriendly system that could handle EV applications. "The development of batteries for automotive use goes hand in hand with a rising demand for scarce raw materials," Hilgert said. "Diversification of cell chemistries is a promising approach to respond to market fluctuations and at the same time minimize system costs."

Avoiding Lithium-Ion Battery Pain Points

Sodium-ion batteries (SIBs) are typically cheaper and more sustainable than conventional lithium-ion batteries but tend to have lower energy density and a shorter cycle life. Traditional lithium iron phosphate (LFP) batteries are known for their stability and long cycle life but have lower energy density than lithium-ion batteries. Meanwhile, solid-state batteries (SSBs) are known for having higher energy density than lithium-ion batteries.

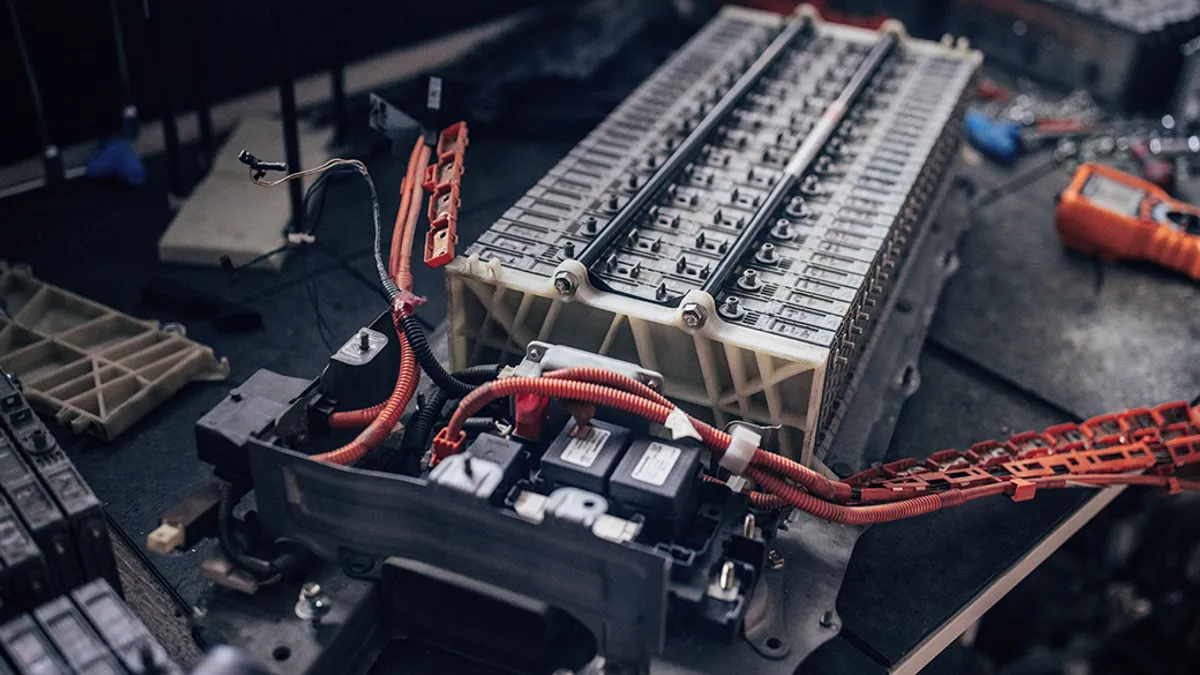

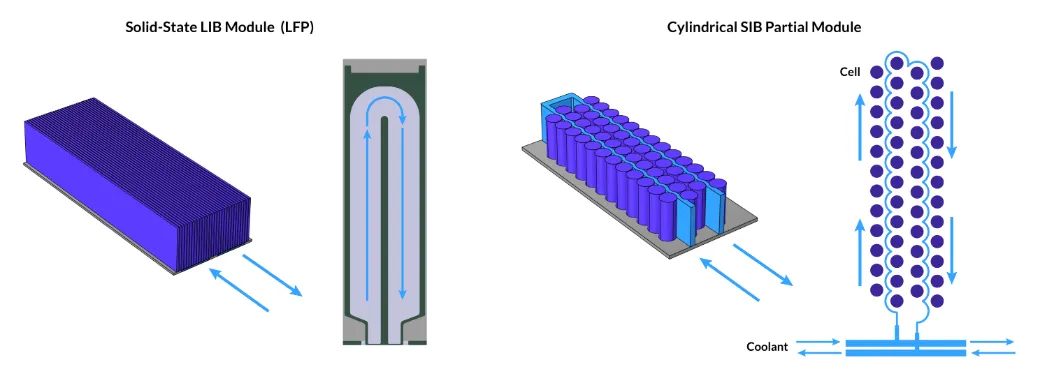

The design team chose to pair an SIB and an LFP-SSB because of the chemistries' unique ability to complement one another (Fig. 1). The idea was that channeling the waste heat from the SIB into the LFP-SSB would rapidly activate the latter's solid-state cells and push them into the higher temperature ranges where they perform best — while simultaneously keeping the SIB from exceeding its maximum operating temperature and increasing the system's overall energy efficiency.

To design and validate its twin-battery solution, IAV turned to multiphysics simulation.

Designing the Battery System

Using a twin-battery model developed in the COMSOL Multiphysics® software (Fig. 2), IAV engineers were able to tweak different parameters (impacting, for example, circuit cooling or the maximum power of cells at a certain temperature) and alter the design for efficiency.

The model showed very fast on-demand activation of solid-state cells, with partial preconditioning done by the SIB's waste heat. The team has optimized the cells' thermal management and shortened the time and energy input needed for SSB activation in cold conditions.

"The simulations showed that it is actually possible to do what we had in mind," Hilgert said. "The waste heat actually can be transported by the cooling system, and the amount of heat is sufficient to heat up the other part of the battery."

Democratizing the Twin-Battery Model with Apps

IAV’s engineers often package a model's functionality into a simulation app, a custom-configured user interface with restricted inputs and outputs that customers can use to run simulations and evaluate results (Fig. 3). Design engineers using the twin-battery app, for example, can view the internal cell states and make changes to the cooling system as they evaluate the varying battery performance.

App users do not need in-depth knowledge of the underlying complex model; instead, simulation apps are designed to be easy to use and hard to break, making them ideal for IAV’s many customers who "want to distribute these simulation tasks to people that usually do not do modeling," as Hilgert put it. “We can hand [the app] out to everybody, and nobody will have a problem using it," shared Hilgert.

Streamlined access to simulation results leads to more efficient development processes and has greatly improved the acceptance of model-based development both internally and among IAV's customers.

(T)Winning the Battle for a Better Battery

IAV hopes that its twin-battery design concept will function as a showcase to others in the battery industry. "The twin-battery approach gives the car manufacturer or the battery designer more options to solve their problems," Hilgert said.